MPTOP Gasket Kits

MPTOP gasket kits are manufactured using top quality raw materials will advanced high-tech production technology.

We offer a comprehensive range of quality seals and gaskets that are manufactured according to specifications of the original parts to ensure optimal fit and performance.

Gasket types:

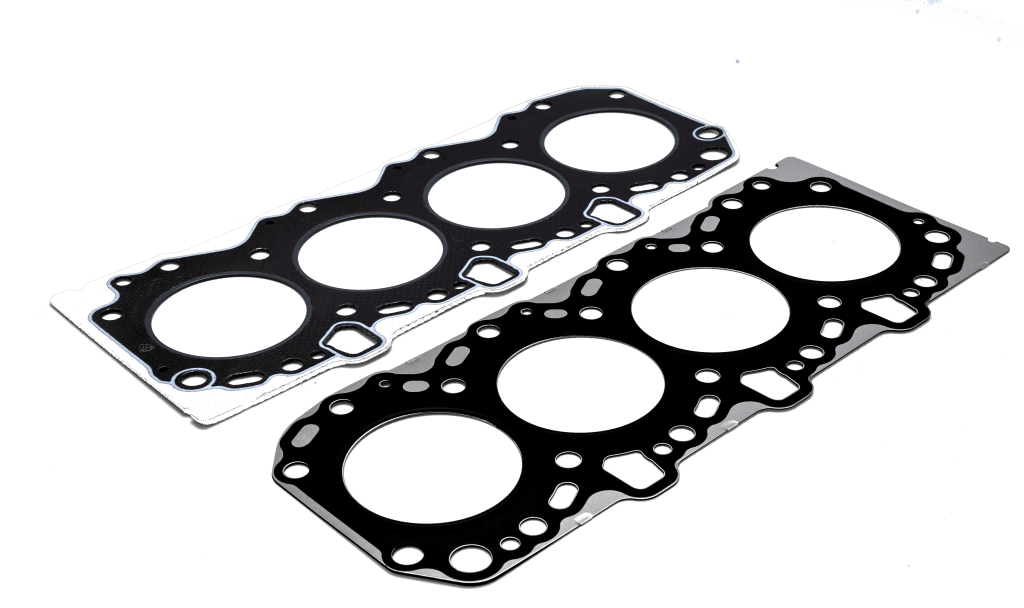

- Cylinder Block Gaskets

- Manifold Gaskets

- Valve Cover Gaskets

- Oil Pan Gaskets

- O-Ring & Oil Seals

- Valve Stem Seals

Material Series

NY300 – Oil Resistant Compressed Asbestos Rubber Sheet

Main Materials: High quality low-chlorine asbestos fibre and oil resistant synthetic rubber

Application: Sealing gasket for engines and flanges of heat & oil, petroleum cracking, coal distillation

Processing: Vulcanised after compression by roller

Tensile Strength: ≥ 12.7 MPa

Compressibility: 7∼17 %

Recovery: ≥ 50 %

Stress Relaxation: ≤ 45 %

Density: 1.6∼2.0 g/cm³

Flexibility at room temperature: Bend 180° on rod with diameter which is 12 times the nominal thickness of sample – NO CRACK

Max Temperature: 300 °C

Maximum Pressure: 3.0 MPa

XB200 – Compressed Asbestos Rubber Sheet

Main Materials: Asbestos fibre and natural rubber

Application: Suitable for sealing gasket for engines, pipelines, flanges with solvent

Processing: Compression by roller

Tensile Strength: ≥ 6.0 MPA

Aging Coefficient: ≥ 0.9

Ignition Loss: ≤ 30 %

Compressibility: 7∼17 %

Recovery: ≥ 35 %

Stress Relaxation: ≤ 50 %

Density: 1.6∼2.0 g/cm³

Flexibility at room temperature: Bend 180° on rod with diameter of 12 times the nominal thickness of the sample – NO CRACK

Test for Nitrogen leakage (500ml/h•mm) Using Heat & Pressure – No leakage within 30 minutes

Temperature: 190∼200 °C

Steam Pressure: 2.0∼3.0 MPa

Maximum Temperature: 200 °C

Maximum Pressure: 1.5 MPa

Thickness: 0.5∼6.0 mm *(Tensile strength NOT applicable for thickness over 3.0 mm)

SS350 – Asbestos Rubber Sheet With Steel Net (Graphite Surface)

Main Materials: Asbestos fibre and natural rubber on two outer surfaces with steel net in the middle

Application: Sealing gasket sheet for engines, pipeline, flanges where temperature is below 510 ºC

Processing: Compression by roller

Compressibility: 12 ± 5%

Recovery: ≥ 40 %

Stress Relaxation: ≤ 50 %

Maximum Temperature: 350 ºC

Maximum Pressure: 5.5 MPa

Thickness: 1.5∼3.0 mm